Street Rod Hot Rod More Stuff Included Lower Price

| Make: | Ford |

| Model: | Model T |

| Year: | 1927 |

| Mileage: | 666 |

| Vehicle Title: | Rebuilt, Rebuildable & Reconstructed |

| Item location: | Mesa, Arizona, United States |

1927 Ford Model T Additional Info:

*** REVISION, EDITED, MORE STUFF INCLUDED, PRICE LOWERED***

I know there are some real builders out there who recognize what's being offered as I have had numerous emails from around the country complimenting me for my build. My almost '27 Ford Style Roadster being offered for sale due to my age and health problems.

For reference, look at the great cars being offered for sale on eBay like these two; item numbers 16269764604 for $35,995. and 322793377297 for $35,900 and my favorite 172898961264 for $60,000 complete with the asphyxiation exhaust pipes that must sound great.The purpose is to illustrate some other examples of current rods for sale and ask...

How much do you think it will cost you to finish my car and have a rod that would easily out shine, out value so many others you see on eBay?If you want a street rod that you can complete and be proud of that's actually worth more than much of what you find on eBay, you’ll need to start with something more unique and more sophisticated than a rusty Model A frame and off the shelf or old used stuff. My car doesn't have windshield wipers but nor do most of the 35 thousand dollars (and $60,000) cars either... LOL

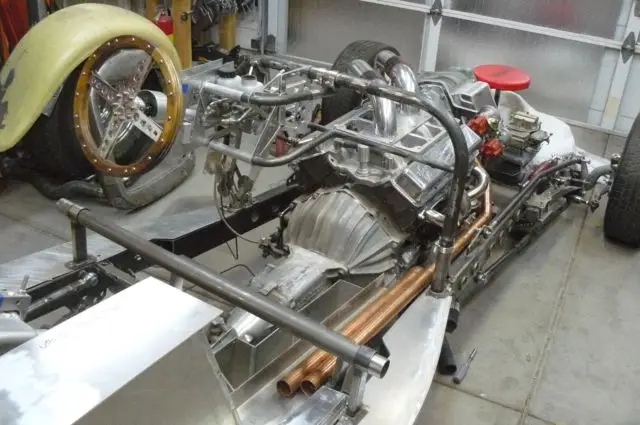

Frame: 2"x 4" Steel tube, tapered both ends 30 + holes filled with with stainless steel tubes TIG welded in with stainless filler rod. Holes along any frame that are not filled with tubing like mine will fill with dirt, stones and mud. These tubes should be polished inside after frame is powder coated or painted. The front cross member is 3" steel. A second cross member with more SS tubes is located where the front spring mounts attach to the frame for added torsional rigidity. All brackets CNC milled, most are surface ground, all are TIG welding with stainless filler rod. Wheelbase about 123". Frame is about 6" wider than typical 26/27 frame.The step mounted on the passenger side of the frame is from a Bell 206 Jet Ranger helicopter. The Trans crossmember uses clear red Urethane skateboard wheels for the trans mount. They are about the same durometer as a urethane mount. An aluminum battery box is included.

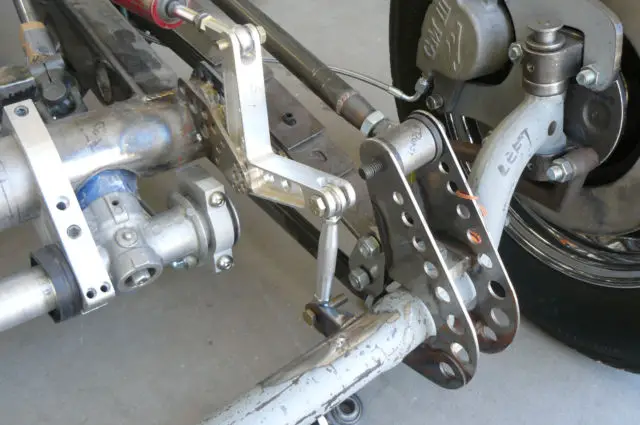

Front End: Chassis Engineering (Iowa) real forged, not cast, dropped axle. Chassis Eng. forged steel spindles. Quarter elliptic front springs with rubber cushioned 4130 shackles. A bracket behind one front spring allows fore and aft adjustment of the front axle to establish proper wheel alignment and tracking in addition to the adjustable four bars.

Four Bars: Fronts, 1" dia. 4130 steel tube radius rods with rubber cushioned front rod ends. ⅝" spherical rod ends at frame. Rears are 1.25" 4130 tubing with rubber cushioned ends and 3/4" rod ends to frame.

Steering: Three piece ¾" 4130 steel tubular steering shaft with Woodward Steering plated U-joints. Tilt steering with partially collapsible steering supports. I made the steering wheel from aluminum with Koa wood shipped home from Hawaii. Center take off GM rack and pinion steering with 1" 4130 tie rods to Chassis Eng. forged steering arms. Wheels are 14 x 6 '35 Ford style chrome wires.

Brakes Front: New Chevy brake rotors, Wilwood aluminum calipers. Stainless steel lines. Tildon master cylinders with Wilwood balance bar for adjustable front to rear brake bias. Stainless Steel Lines Hydraulic clutch with Tildon master and Ford slave cylinders, stainless lines. Firewall hoop supporting steering and master cylinders. is 1.5" 4130 steel tube. Custom made CNC aluminum brake and clutch pedals.

Brakes Rear: Disk brakes with new 11" rotors and new Cadillac calipers, stainless stainless brake lines and cable operated parking brake.

Rear End: 10 bolt Chevy with a Model A buggy spring. Four bars are 1.25" 4130 steel tubes with .750" rod ends at frame and rubber cushioned ends at rear. Panhard bar is 4130 steel tube with cushioned ends for added stability. Rear spring shackle mounts have ball thrust bearings to allow the rear axle to move up and down in an arc without twisting the spring or spring shackles, clever huh. Everyone is welcomed to copy this. Wheels are 15 X 8 Chrome just to replace the wire wheels that leaked even after sealing again.

Fuel Storage: The design is based on two gas tanks made from .125" aluminum. Total capacity is about 14 gallons. Though one tank may prove sufficient. The larger tank sits down in the frame. The smaller tank sits next to the radiator behind the seats.The filler cap is made from a Hughes 269 Helicopter main rotor blade dampener.

Engine: It's a '75 350 Chevy four bolt 010 block bored .030" over with all new complete rebuild kit with cam bearings installed, pistons fit to rods. Ten under crank, new bearings, mild cam, hydraulic lifters, oil pump, timing chain set and gasket set. Heads are bare stock cast iron used for making exhaust. The plan was to buy Edelbrock, Made in America, aluminum heads. A compact starter is included.

Exhaust: Stainless hugger headers and carbon steel exhaust pipes and small diameter tubular glass pack mufflers. The carbon steel pipes (now behind aluminum side panel can to be used as patterns for SS pipes and SS mufflers that would to be unshrouded and exposed for a more stunning presentation.

Engine Cooling: A new aftermarket aluminum radiator is mounted in the rear. Two new 16" American made Flex-A-Lite S Blade electric fans are included. Piping to and from the engine is 1.5" copper pipe with rubber hoses to isolate vibration. New aluminum water pump. Cooling air flow uses a louvered aluminum panel to be molded into the driver’s side body to direct fresh air behind the seats to the forward tilt mounted radiator. That louvered panel is a rare find. It’s the APU (Auxiliary Power Unit) air intake panel from a Bombardier Canadair Regional passenger jet plane. This panel is several thousand dollars if you had to buy one from Bombardier…. Not you would be doing that. I was fortunate to be able to buy this one for considerable less.

Blower: A 4-71 on a uniquely designed (design protected) belt drive to run the blower off the front of the engine with the blower protruding the grill shell - hence the rear mounted radiator. Project includes two Holley carbs, a spread bore and a square bore. Additional aluminum tube bends are included to finish connection between blower and the new Weiand 6-71 blower manifold.

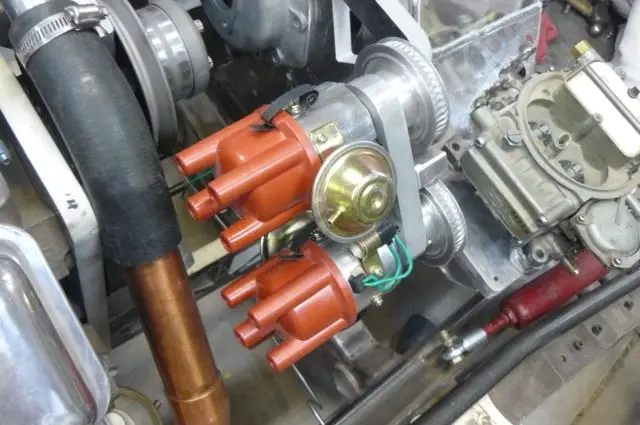

Ignition: Dual 4 cylinder VW distributors are a very unique design (design protected) and are belt driven. The oil pump is driven by a modified Chevy distributor. A Chevy stock distributor included for engine break-in.

Trans & Clutch: It's a Muncie 4 speed and includes a fresh rebuild kit to be installed. The flywheel is 153 tooth aluminum Weber style with a steel face and a new Borg & Beck Pressure plate.

Body: Fiberglass '27 with turtle deck removed to add or build a pickup bed. The body has been cut the long way to widen for the wider frame. Rear fenders are '30-'31 model A Ford. Front glass fenders are some unknown car - maybe a kit car. The Grill Shell is a modified, enhanced after market steel shell. Seats, not shown, are from a Bell 222 Helicopter.

Misc: Many of the bolts included are grade 8 to be used for final assembly. Lower grade butter bolts are holding things together for now. I have CNC machined brackets to add a bolt on roll bar to the design. Also included is a polished liquid filled all copper fire bottle from a Hawker Corporate Jet Plane with two electric squibs the could be made functional... with properly protected manual arming and manual and automatic firing circuits. A couple of sets of 3" five point belts are included.

Just Added: Depending on final bid, I have some other items I can include in this sale. I have a Hurst shifter that’s disassemble for the purpose of plating it in Zinc Dichromate that I didn’t get to. Also I more than a hundred dollars worth of Fiberglass materials for body work comprising; Urethane, Styrofoam and Divinycell foam, poly resin, hardeners, body filler, resin mixing cups, sticks, vacuum bagging supplies and a MDF plug to make a fiberglass tailgate for a pickup bed that accentuates the shape of the rear frame cross member and some misc electrical items including all one color white wire. It's the way aircraft are wired. I also have some extra cost aircraft flight instruments I was going to put in the dash panel and can show the winner a CAD drawing of my planned panel. And I have two 28V NiCad batteries from a Bell Jet Ranger helicopter that can be converted to 12v and will need to be properly charged. These are optional.

Payment: A $500.00 Non-refundable within 48 hours of auction end. That $500.00 will be deducted from the selling price. The project must be picked up in south east, Mesa, Arizona. Final payment is to be by wire transfer, cash or Cashier's Check. Payment is due at time of pick up prior to loading anything. Pick up must be made on a day during regular banking hours as the transaction will take place with cash or Cashier's Check and buyer ID that will be verified by the bank. I will need the Cashier's Check information a couple business days to verify and hold your funds before you arrive.

Warranty: None. No warranty or title of any kind including functionality, suitability of any purpose or design or components is expressed or implied. Any needed design changes or other any other changes or additions to the project are the responsibility of the buyer and subsequent buyers. Inspection and compliance with all Federal, State and locals laws are the responsibility of buyer.

Pick Up - No Shipping: You'll need a trailer and might be able to rent a one way U-haul trailer. Be sure you check with U-haul as they have strict requirements for your tow vehicle. It would be best if you were to bring a pal to help you load as I am not able to help very much at all die to health. If you're a Good Guys or NSRA member you may find a local member to help you load. Allow time to disassemble and load as needed. I have a Cherry picker to use. You may need to arrange to stay somewhere overnight.

This an untitled, street rod that is not a bolt-together kit. I made this myself - I used to teach machining and CAD/CAM. I designed the car on my CAD program affording the opportunity to be more sophisticated and technically advanced so no one will think this came from a some catalog. This is a deal where the majority of the difficult work in done. There is still work to be done by someone with skills a bit beyond bolting stuff together. And I know you’re out there.

Contact me by email prior to by bidding to discuss details. I have no particular interest in calling you, only because I get these dopey emails from Craigslist saying; " you still got this call me". I don’t respond to those. Verbal communications aren’t worth the paper they’re written on.

The car is also advertised locally and in several other areas

Thanks for getting through all this,

Doug