1965 AC Arntz-Butler Cobra Custom Show Car Concour Race Car >$100K Invested Rare

| Make: | Shelby |

| Model: | Cobra |

| Type: | Convertible Roadster |

| Year: | 1965 |

| Mileage: | 12829 |

| VIN: | CA458600 |

| Color: | Gray Metallic Two Tone |

| Engine: | 406 - 512 HP |

| Cylinders: | 8 |

| Fuel: | Gasoline |

| Drive type: | RWD |

| Drive side: | Left-hand drive |

| Vehicle Title: | Clean |

| Item location: | San Clemente, California, United States |

1965 Shelby Cobra Additional Info:

1965 Arntz-Butler Shelby Cobra

Probably the “NICEST” Restored/Modernized Arntz Cobra in Existence

THIS IS NOT A “KIT” CAR

Built by:

Steve Arntz - Designer for Shelby Racing 60’s

Ron Butler - Crew Chief Shelby Racing 60’s-70’s

Year Originally Built: 1980

Ground-Up Custom Restoration 2009-2013

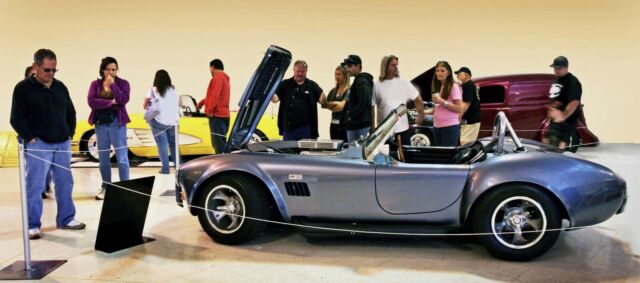

Three Time First Place Winner at Sacramento Autorama

First Place Winner 2013, 2014, 2015

“Production Road Racer Class”

CA SB 100 Title

(Smog Exempt Forever in CA)

12829 Miles

Weight: 2600 lbs

Chassis

Chassis # CA458600

Parallel Ladder Frame:

3” x 4.125” main rails; wall tubed, massively X-Braced

(twice as strong as original Cobra)

56% Weight to Rear

Engine & Trans

Small Block Chevrolet

406 cubic inches

Ported & Polished Roller Engine

512 HP Comp: 10.0 : 1

Builder: Horse Power by Gerolamy

(complete specs attached in picture section)

750 Speed Demon Carburetor

Accusump Oil Accumulator

Muncie M22 4-speed “Rock Crusher”

(Brand New Aluminum Case)

New Clutch

(replaced during restoration)

Front Suspension

Front Rack & Pinion Coil Over

by Hawk Cars, Ltd. England

(replaced during restoration)

Adjustable QA1 Coil Over Springs/Shocks

Rear Suspension

Jaguar XKE IRS with 4 - QA1 Coil Over Springs/Shocks

(Total of 6 - QA-1’s in Suspension at $1000 each)

Final Gear Ratio: 3.08 : 1

CUSTOM ALUMINUM FUEL CELL

by Jay’s Hot Rods

($1200)

ET 2-Piece Bolt Together 15” ET-III Racing Wheels

(Custom Made for this Car)

Nardi Wood Steering Wheel

New Autometer Gauges

AC Pedals

Heated Seats

Extra Stuff

Hot Rod Magazine

June 1980 Issue

Cover Story Arntz Cobra

Sports Car Graphic

July 1981

Cover Story Arntz Cobra

Original Arntz Cobra Brochure

Optima Battery

Secondary Battery Holder

(built for Heavy Duty Optima Battery or other)

Various Plexiglass Visors

Full Tonneau Cover

Fire Extinguisher w/Billet Style Holder

5 “ Book of Build Receipts from Restoration

Folio of Engine Specs - Documentation

Instructional Manuals for Almost Every Component

done during the custom restoration

Start-up Video:

https://youtu.be/_kfI-N2bnxY

Walk-Around Video: (super sunlight condition, washed out)

https://www.youtube.com/watch?v=KO4TuDVeD0o&list=UU6qW2o4AvhN9A0gplIPhQeA&index=40

There are over 200 pictures of the automobile hosted to this ad that load below the text. If you have a older/slower computer or internet connection it may take several minutes for all the pictures to load. If they do not load you can access my Photobucket account to view all the pictures in large format at this link:

http://s669.photobucket.com/user/fmattingly/library/Cobra%20Arntz%201965%20DK

(the best way to view the pictures is to go to this link, click on a picture and blow it up to full screen… Also, all 200 pictures will load below this text and if you click on the picture it will blow up)

I am selling this car for a friend. I have been involved with classic automobiles for almost 40 years. I have built and restored many Corvettes and Porsches and am a member of numerous car clubs including PCA & NCRS. I have judged at many of the top concour events in and around Southern CA. This is a stellar, turn-key automobile at the highest-level of restoration. This is a concour quality custom built show car, that won the Autorama in Northern CA three years in a row 2013-2015.

This Arntz-Butler Cobra is an exact “replica” of a 1965 Shelby Cobra was built by the legendary Steve Arntz (Shelby Designer) and Ron Butler (Shelby Crew Chief) in 1978 and from 2002-2013 was completely restored and further customized & modified to near perfection. Arntz from South San Francisco worked with Carroll Shelby on the original Cobras and went on to be the first builder of Cobra replicas in the late 70’s early 80’s.

Arntz & Butler launched the craze in the American Aftermarket Cobra cars. The car was completely built by craftsmen dedicated to the Cobra Cars with workmanship of the highest caliber. The custom-built chassis is a work of art with six QA Coil-overs own and the power comes from a 406 Chevy Small Block producing 512 hp, hooked up to an M22 “Rock Crusher” 4-Speed Transmission., which is attached to a independent Jag rear-end.

His cars were built with incredible attention to detail, with significant improvements to the original Cobras, especially in the area of performance and safety. He designed his cars as turn key examples for possible sales to Ford Motor Co, but were never put into Ford’s production line. All his cars were built with Ford or Chevrolet engines during his production run.

This quality of this build and the amazing handling capabilities of this vehicle will surpass any original factory Cobra. It is the strongest, sturdiest and heaviest frame of any Cobra ever made, and with the Jaguar XKE center section, this car is capable of withstanding incredible torque output from any modern aluminum Chevrolet power plants as used in McLaren Can-Am race cars.

The Shelby Cobra was so successful that once production ended in 1967, it became the car that spawned the most replicas ever in the world! Steve Arntz & Ron Butler among the first to start producing a roadster in 1976 that replicated the Cobra 427 S/C. Consisting of a square tube frame and a fiberglass body whose molds were formed from an original model from 1965, and thus offering an almost perfect likeness.

The car we offer is equipped with a Chevrolet 406 cu in V8 with whose tuning, according to the previous owner's information, is good for 512 hp, with an Edelbrock intake manifold & Speed 750 Demon carburetor. The car is lighting face and sticks to the road with massive 10” wide Cooper “Cobra” performance tires (P295/50R15) on the rear and 9” (P265/50R15) on the front.

The engine is mated to a Muncie M22 4-speed “Rock Crusher” and the car features independent Jaguar rear suspension, plus four-wheel disc brakes. The interior displays beautiful (new) Auto Meter Instrumentation, and G-Force harnesses. Many of the detail accessories are from Shelby American, which gives the car a certain flavor of authenticity. Roughly 65 units were produced between 1976 and 1981.

These cars were built to be road racers, and while extremely fast out of the hole, these cars were designed more for high-speed road handling. The cornering capabilities on this Cobra is simply mind-blowing. The road manners out on the freeway are incredible and as solid as some of the best road racers on the planet. The vehicle is comfortable and SOLID while sitting at idle (zero cowl shake) or out on the road at 100 miles per hour.

An original 427 Cobra today is in the $1.2M range and is an amazing collectable no doubt, but here we have a substantially better machine at less than 1/10th the price. Arntz Cobra’s are extremely rare, with a number less than 100 (from my research 65 were made) ever built by the Arntz/Butler factory team as replicas. I want to emphasis, this is not a kit car. This car was completely built as a finished car by Arntz and Butler. This car was similar to what Ford did in the 2005-2006 Ford GT’s, which were a replica in modern standard formulation to emulate the original Ford GT’s. Arntz & Butler were essentially doing the same thing with their Cobra “Replicas”. These were not some car pieced together by some guy in his garage. These cars were designed and built by the same guys that built Shelby’s Cobra’s and GT40’s. The restoration process to this particular vehicle was done to concour quality standards with many modifications to make it even more desirable than it was when originally built by Arntz & Butler. This Cobra is a masterpiece work of art.

I cannot emphasis this enough, you are not looking at some pieced together kit Cobra, this is the real deal built by two guys that worked hand and hand with Carroll Shelby, building race-cars. These guys were engineers of the highest order. They took all the weaknesses in the original Cobra’s and fixed them. If you live in Southern California or have the ability to fly in and look at this elaborate piece of automotive history please try to come check it out. The sight, the sound and the driving experience is like no other Cobra I have ever witnessed. The handling capabilities are simply superb. The “stout” frame gives the car a definitive feeling of confidence. Please take the time to read the specifications built into the Arntz Cobra.

About Steve Arntz, Ron Butler & Their Cars

A bit of Steve Arntz and Ron Butler information and history: Steve Arntz & Ron Butler worked with Carrol Shelby on the original Cobra's and after that project ended he continued and was the first man to build a Cobra replica. Steve Arntz started the replica Cobra industry, enabling so many to own their dream car.

In the pictures near the end there is a picture of the GT40’s being prepped for a race, the next picture is a closeup of the text under the picture with the names of the gentlemen pictured. Ron Butler’s is pictured and named in the text.

Here are some comments of what others say about the men and the cars they built..

"This all started with the first clone Steve Arntz body…”

"Virtually all the Cobra Replica manufacturers that came in the years after us bought cars and chassis from us - ALL."

"Produced by Steve Arntz and Ron Butler in the late-70s, this American made Cobra reproduction is as rare as it is stunning. Arntz was a pioneer in the concept of reproducing Shelby Cobras & this vehicle is testament to the quality of his workmanship. These cars are not the same as the kit cars that are being sold today. There were very few of these cars built and even fewer on the road today."

"Steve Arntz started building replica cars in 1972 in South San Francisco. Steve is and always will be an R&D man. He'd build a car, drive it for an hour, and then tear it apart again. This went on consistently. By the time I met him in about 1989, he had a shop at Sears Point. The one thing that everybody agrees on, is that Steve & Ron were light years ahead of any other replica builders. He never sacrificed quality for price. If you could see a Arntz-Butler car, next to pretty much any other manufacturer, you would see the difference in quality and safety features, many of which are incorporated in other cars today."

“The Arntz Cobra has a unique steel structure that separates it from all other Cobra replicas. One of these features is the steel door beams and hinge designs that are fiber glassed into the doors during construction. There were dozens of jig fixtures that were included with the tooling and fixturing of the body mold "package" that insured the proper location of all these components. You might have a similar "body" mold (the body is easy enough to splash), but without all the other components and the knowledge that it takes to put it all together in order to duplicate the Arntz design, you don't have anything any better than 90% of the rest of the wannabe’s out there. These were some of the primary things that made (makes) the Arntz so different and so much better that most (if not all) others. Giving credit where credit is due, the Arntz was originally designed to be a Cobra that one could drive every day. I saw a demo that Steve Arntz had which had well over 100K mi. on it. It was in better condition than a lot of production cars of today.”

“What most people don't realize is that the Arntz-Butler Cobra, back in the 70’s-80’s, was a FULLY engineered car. When he went to Ford, there was a manufacturing blueprint drawing for every single part on that car. Hundreds of the best quality (back then hand drafted) drawings and spec sheets you could imagine. I saw them. There isn't another replica out there which can match it's quality and engineering, even to this day, AFAIC. I was willing to put my name and stake my reputation on it.”

The quote below was taken from a Los Angeles Times Article from 1988:

https://www.latimes.com/archives/la-xpm-1988-10-07-vw-3520-story.html

--Ron Butler, 54, New Zealand-born president of Ron Butler Racing of Goleta, has been building Ford-powered Cobra replicas for 10 years and has sold 60. Butler is former crew chief on the racing team of designer-driver Carroll Shelby who built the original Cobras.

“I’ve counted the number of companies (worldwide) making the Cobra and there are 87,” said Shelby, now head of Shelby Automobiles Inc. of Whittier, a high-performance consultant for Dodge. “But his (Butler’s) Cobra is a good one. Ron doesn’t do anything that isn’t first class and he is one of the few Old World craftsmen left.”

That’s right from the mouth of Carroll Shelby himself.

THE ENGINE IN THIS CAR

Gerolamy Engine Specifications: (picture included from stat book)

Engine: 400 Chevy Block: Chevy Deck Height: 9.0 Hone Finish: 400

Main Bolts: Chevy Crank Shaft: Eagle 4340 Mains: STD Rods: STD Stroke: 3.750

Rods: Pro-lite I Beam RPM-6000 Rod Length: 6.0 Bolts: ARP # 7/16

Pistons: Ross #99531 Type: Dish Top -20.0

Top Ring Groove: 1/16 2nd Ring Groove: 1/16 Oil Ring Groove: 3/16

Rings: C2A # RS-500 Type Top Ring: Moly Second Ring: Cast

Cam: Crower Type: Hyd-Roller Lifters: Hyd-Roller

Timing Set: Cloyes Type: Hex Adjust

Oil Pump: Melling M-55 Pump Drive: Melling #SH-55

Gasket Set: Fel-Pro Freeze Plug Set: Brass Fastener Set: SS

Cam Bearings: Duro-Bond #CH-8 Main Bearings: MS909P #STD

Rod Bearings: CB663-P #STD Timing Cover: Cloyes 9-221

Head Gasket: Fel-Pro #1014

Cylinder Heads: Edelbrock Chamber Volume: 64 ca

Valve Job Int: Edelbrock Exhaust: Edelbrock

Intake Valve: Edelbrock Head Dia: 2.02 Stem Dia: 11/32

Exhaust Valve: Edelbrock Head Dia: 1.6 Stem Dia: 11/32

Valve Guides: Bronze Clearance Int: .002 Exh: .002

Valve Stem Height Int: —- Exh: —- Springs: 6105 #Isky

Spring Pressure Closed: 135 lbs Open: 325 lbs

Installed Ht. Int: 1.80 Exh: 1.80 Coil Bind: 1.120 Retainer to Seal: .900

Retainers: Edelbrock Spring Cups: Edelbrock Studs: 7/16 #ARP Guide Plates: Manley

Rocker Arms: H&S 1.5 Int: 1.5 Exh: 1.5

Int Push Rod Length: Stock Dia: 5/16 Ends: 5/16

Exh Push Rod Length: Stock Dia: 5/16 Ends: 5/16

Port & Polish and any other modifications: F.E.S. port work Tom Lucas, 10 + 01 C.R.

Webster Stud Girdle

Geology Engine Balancing Specs: See Pictures

Camshaft Specs: See Pictures

The 406 small-block engine in this beast is the perfect blend of power and torque fitted to a lightweight racing specimen. The power is incredible, the sound is intoxicating and the ride quality and safety features of this machine are about as good as it gets. This is about as much fun as you can have with an automobile.

Okay okay… some will say “how can you put a Chevy engine in a Shelby Cobra”… I say easy and the truth is that is exactly what Shelby himself wanted for the Cobra. Carroll went to GM first but Chevrolet knew he would kick the Corvette to the curb if they gave him their engines. Ford was actually his third choice. If you want performance and reliability out of a small block motor, this is it. This 406 produces 512 HP in this little 2600 pound Road Rocket. Coupled with the M-22 “Rock Crusher” makes for a machine that is virtually unmatched in performance.

Watch this video of Carroll Shelby talking about his desire to use Chevy Engines initially and was turned down by GM because they knew he would beat the Corvettes on the track. Fast forward to the 7:40 mark on the video to hear Carroll in his own words.

https://www.youtube.com/watch?v=oKYoxGv_llI

Link to an article about Shelby and Chevy:

https://www.nbc-2.com/story/11723174/when-ford-met-shelby-the-story-of-the-shelby-cobra

This little gem was meticulously restored over about a seven to eight year period. The original car was a near perfect example of the Arntz Cobra before the custom project was begun. The partial receipts in the extensive folder with the car total over $56K since 2002. However, there are a lot of things that are not found in the receipts. For example the ET Racing Wheels are somewhere in the $800 each category. These wheels were MADE for this car. There was over $30K of body and paint work done by the custom builder at his friends high-end paint and body shop in Northern California. Over 1000 hours was put into the custom build of this car. The car has been meticulously cared for and has less than 13K miles on the odometer. Since the body and paint and full body off restoration probably less than 2500 miles.

Couple the original cost of the nearly perfect Arntz example that was used in 2002 and you come up with a car that was easily over $100K to build.

Paint & Body

The color is a Dodge Viper Graphite Metallic on the Hood/Trunk Stripe and the body color is a 50% reduction of the same color. The most interesting thing to me was how many different shades it takes on during the day, depending on how much light is directly or indirectly on it. The beach pictures were taken on a very blue-sky morning and the color takes on a wonderful blueish hue. A lot of direct sunlight like we had in the video gives it a very light gray/silver tone. At dusk, the color is much darker. Overall, in a moderate light or garage setting I would say this color is a medium gray. It’s one of the most striking colors I have ever photographed on a car and is just stunning when viewed in person. It’s a very similar color to the 2005 Ford GT Tungsten Gray Metallic; albeit more vibrant. The picture with the people gathered around the car at the Sacramento Autorama seems to capture the truest color of the car to my eye, however there a lot of lights in that building.

(Note: The walk-around video was shot during high-noon with an older iPad - the quality is awful and the color of the car looks completely washed out. It actually shines like a diamond out in the sunlight, please view the pictures for the true look)

Make sure you check out the pictures showing the hood and trunk (in open position) stripes as they are “flip-flop” painted on the inside to match the outside. It’s a total WOW. I cannot stress enough the quality of this paint job. The man that did the custom build restoration is an incredible body fabricator and one of his buddies is an amazing body-man and painter with a very high-end shop in Northern CA.

Take note of the picture in the garage from the rear of the car with a clear shot of the ten inches of tires underneath. The rear fenders were modified almost 1.5” to accommodate this look. I’ve never seen such an amazing rear-end on any Cobra like this one.

If this Cobra was rolled onto the lawn at Pebble Beach, there would be a crowd around it all day. It’s just that nice. The fit and finish is near perfection.

Take note of the way the Cobra emblems front and rear and how they were inlaid into the fiberglass. Also, notice how the gas filler was cut into the body behind the seats and “cupped” down under the glass. Normally they are simply “plopped” onto the outside and stick out like a giant cork from the body. Also, check out the custom vents in the hood to match the design on the engine pieces.

The previous owner designed most of the elements under the hood, including the valve covers, intake surround and vents in the hood. All these pieces were custom CNC made for the car and they all combine to make for a most unique custom Cobra. You will never see another vehicle with these design elements under the hood, they are all custom-made one-off pieces.

Custom Treatments:

Gorgeous CNC Aluminum Pieces throughout the car. This was all designed, drawn and milled to perfection. You will never see this one of a kind fabrication on any other car anywhere. These pieces were all made custom for this car at a considerable cost.

Rearview Mirror

Cowl Vent - for access to Distributor

Hood Ventilation Intakes

Valve Covers

Air Cleaner Cover

Custom Made Aluminum Slide-Out Battery Tray

Custom Made Gas Tank (Blader-Style)

Take notice at the way the emblems are inlayed into the fiberglass body instead of the typically stuck on tacky look. I took a close up of the rear emblem so you could see the perfection to the edges surrounding the emblem. This takes hours and hours to perfect. These little details are what makes this car “pop” when viewing at a high-end show venue. The body on this car is probably one of the most perfect bodies of any Cobra anywhere, with over 1000 hours of man hours to build. Arntz and Butler were freaks when it came to the hand laid, perfect smoothness to their bodies. The body panels are all hand laid to a thickness of 3/16th to 1/4” all over, even on the inner panels, which are all bonded to the outside body panels. There are no rattles, no noises coming from the body on this car. There is zero cowl shake on this car. The fiberglass panels are thick and stronger than steel, not paper thin and flimsy like most of the cheap replica kit bodies that are currently in vogue. This is old-school craftsmanship done by a couple of master craftsman.

Engineering the Arntz Cobra - the following text is taken from the Hot Rod Magazine June 1980 Issue showcasing the Arntz Cobra and is said best in the words of Steve Arntz. The car was featured on the front cover and a pristine example of the magazine comes with the car.

“As good-looking and as quick as the Arntz Cobra is, the thing Steve Arntz and Ron Butler are proudest about is its engineering; and they would rather talk about the strength of the doors than discuss how faithfully the body resembles the original 427 Cobra. They set out to make his car better than the original (having owned several AC Cobras, he was well acquainted with the car’s shortcomings) in terms of safety, reliability, handling, passenger comfort and performance.”

“As an example of the improvements made, the original Cobra was nose-heavy, which caused excessive rear wheel spin during hard acceleration and rear wheel lockup under braking. Steve moved the engine back (10 inches), which improved weight transfer during acceleration, and gave more rear wheel weight (negative weight shift to the front) during braking. Both features improve handling and acceleration tremendously.” (In actuality these cars were “front mid-engined” cars, much like the new Corvette is a “rear mid-engined” build. The engine is basically sitting in your lap)

“The frame was designed to be more than twice as strong as the original, and the Arntz Cobra can handle the most powerful of today’s high-performance street or racing engines. The rear fender-well design allow 50 percent wider tires than could be fitted to the original Cobra. This means improved traction and smoother ride.”

“No one know the Arntz Cobra better than its designer, so we asked Steve to expound on the features of the car.”

FRAME - “After considerable discussion about what the frame should actually be, we arrived at a parallel ladder design that incorporates 3 X 4-inch steel members of 1/8-inch-wall material comparable to a 1018 SAE grade steel. The perimeter frame rails are 4 X 1.5-inch 1/8-inch-wall steel. These surround the entire perimeter of the passenger compartment, providing not only substantial frame rigidity but some additional safety features as well. The torsional rigidity theses rails create translates into improved chassis stiffness for better braking and cornering.”

“The X-bracing portion of the frame is constructed of 4 X 1.5-inch box steel tubing laid out to accommodate standard-shift 4-speed and Doug Nash 5-speed transmissions, as well as an assortment of automatic gearboxes.” (Note: this car has a new M-22 Muncie 4-Speed “Rock Crusher”)

“Other features, such as solid mounting the Jaguar rear suspension member, add to the net chassis stiffness. The design of a frame that meets our standards is a blend of handling and safety features. If a particular chassis feature looks good but doesn’t contribute to safety or performance, we omit it. The Arntz Cobra is intended as a pure automotive design, not simply something meant to sell.”

“The addition of strengthening gussets and fish plates brings the total weight of out frame to about 240 pounds. Considering the design strength of the frame, it’s very lightweight. Part of this results from use of single-bead, hili-arc, aircraft-quality welds throughout the entire frame.”

(Note: Make sure you take a look at the undercarriage pictures to see the quality of the welding on the frame, simply outstanding)

BODY- “The body is an exact reproduction of a 1967 427 Cobra shape, and we’d like to emphasize “shape”. Structurally, we’ve designed a fiberglass body of superior durability compared to the original aluminum skin. Our body thickness varies from 3/16- to 1/4-inch. Bodies are permanently bonded to the inner panels, which are also constructed of similar thickness fiberglass.” (Note: All hand-laid fiberglass, not choppy gun like most of the kits on the market)

“All the original Cobra external feature integrity is preserved in the Arntz version by offering exact reproductions of the windshield frame and glass, front and rear bumpers, front and rear lighting fixtures, rear-view mirrors and comparable pieces. In fact, we have been able to locate and contract most of the original vendors for AC Cobra accessory parts and offer this for of authenticity with the Arntz package.”

“Each body door has a steel guard rail constructed of 2 X 4-inch 1/8-inch wall mild steel tubing connected to hinges that have been pressure-formed in a huge press. These guard beams and hinges are of sufficient strength that the entire car can be jacked off the ground simply by placing the jacking member beneath the guard beam of the door, which will support the entire raised vehicle weight.” (Note: try doing that on an original Cobra and watch the door snap off. You can sit on these doors with the door open and it cannot budge)

“Inside the driver/passenger compartment, we have given considerable design thought to the dimensioning of foot boxes, arm leg and hip room, so that both persons are functionally comfortable and have optimum road visibility.”

“Our brake and clutch pedal assembly operated on roller bearings with a single hydraulic slave cylinder for clutch actuation and two independent hydraulic cylinders for the brakes. This special-design assembly is also adjustable forward and rearward to accommodate variation in driver leg length. A race-car brake balance bar is also included for front-to-rear brake pressure proportioning.”

“Arntz Cobras have four-wheel disc brakes. This includes the stock inboard-located Jaguar rear disc brakes. In the front, we provide a special Huffaker/Arntz design of superior street capability and worthy of race-car use.

SAFTETY, DESIGN & PERFORMANCE

“Our steering system is rack and pinion, the same design used on the original 427 Cobras. Perhaps the best available anywhere, it adds to the precise control required of any high-performance vehicle.”

Note: This Cobra has a brand new rack & pinion front-end from Hawk Cars Ltd. England with QA-1 Coil-Overs. There are a total of 6 QA Coil-Overs (fully adjustable) in the suspension of this vehicle at a cost of $1000 each.

“Regardless of the type of engine and exhaust system selected, we provide a special heat shield located between the exhaust manifold on the driver’s side and the outside of the driver’s foot box. Not in contact with the foot box or manifold, this shield provides adequate temperature control during times when air flow through the engine compartment is low.”

“This proximity of engine to firewall and foot boxes is the result of having moved the engine 10 inches rearward from where it was positioned in the original Cobras. Where the AC Cobra had about 53 percent of its weight on the front end, we’ve been able to redistribute this so that 56 percent of the total vehicle weight is now on the rear end. Given sufficient tire width and traction, lateral G-forces in excess of 1.5 are easily accomplished.”

Note: The chassis has a built in cage of steel that surrounds the cockpit area of the car. There is a picture of the chassis with no body on it from a magazine article called “Fast Glass”. In that picture you can see how the steel cage is attached behind the cockpit and under the dash. The doors themselves are attached making a complete cage around the occupants. You can also visualize it in the picture showing the drawing of the chassis in the magazine article by Hot Rod.

“We also build and offer a 4-inch-thick-core, special-design radiator that will accept the cooling requirements of just about any engine our customers might choose to install.”

“To sum up its builders words: in our opinion, the Arntz Cobra is more than just another pretty face-it is a totally engineered car backed by a real commitment to quality.”

______________________________________________________________

This rare and unusual Arntz Cobra has got to be one of the most complete and gorgeous examples in the Country. These cars are bona fide rarities and only occasionally come up for sale. This particular example is unique as it is a race car and custom and concour quality show car. If you are looking for a gentleman’s weekend racer and show car all rolled into one, with a unique history and story you may have just found it.

This car is stunning to look at and comfortable and safe to drive at any speed.

If you are in Southern California or can fly in to see this car, you will be amazed at the quality of this unique racer show car.

For further information please feel free to call Frank at 949-310-6262. The owners number is available to serious buyers.

We encourage real buyers to call to discuss this vehicle before the auction ends.

TERMS & CONDITIONS:

The car is for sale locally and we reserve the right to cancel this auction at any time before the end of the auction. We do not have a Buy It Now Price listed.

The car will be made available for inspection by serious bidders throughout the auction. Please e-mail us if you would like to see the car. If you prefer, we can arrange to have a qualified, independent, professional mechanic perform a pre-purchase inspection for you (at your expense). It is the buyers responsibility to verifythat all of the sellers information and claims about the car are true and correct prior to the sale of the vehicle.

Winning bidder must contact us within 24 hours of auction end, and make arrangements for payment at that time. A $1000.00deposit is due within 48 hours of end of auction. The deposit can be made by PayPal, cash (please do not mail cash!), bank check, cashier's check, or bank transfer (preferred). The remainder is due within 7d days of Auction end. The remaining balance must be made in the form of a bank transfer (preferred) Cashier'scheck, or bank check (all forms of payment subject to verification). If no contact is made within 24 hours we reserve the right to re-list the vehicle, sell it to the next high bidder, or sell it otherwise. Please arrange financing prior to bidding. Once the final balance has been paid, title transfer paperwork will be initiated.

Buyer is responsible for pickup or shipping of this vehicle. If you wish to have it shipped using a service, we will gladly cooperate, you can locate shippers by doing a search for “auto shippers”. We have relationships with both domestic and international shippers should you need some assistance.

This vehicle is being sold as is, where is with no warranty, expressed written or implied. The seller shall not be responsible for the correct description, authenticity, genuineness, or defects herein, and makes no warranty in connection therewith. No allowance or set aside will be made on account of any incorrectness, imperfection, defect or damage. Any descriptions or representations are for identification purposes only and are not to be construed as a warranty of any type. It is the responsibility of the buyer to have thoroughly inspected the vehicle and to have satisfied himself or herself as to the condition and value and to purchase based upon that judgment solely. The seller shall and will make every reasonable effort to disclose any known defects associated with this vehicle at the buyer's request prior to the close of sale. Seller assumes no responsibility for any repairs regardless of any oral statements about the vehicle. Please Check My Feedback- I value my 100% positive rating, and will do my best to keep it.

The winning bidder should have the car insured from the time the final payment is made to us. Once final payment is made, we will exercise a generally accepted standard of care, but the buyer assumes all liability and risk once the final payment is made.

Before delivery of the vehicle, the winning bidder must provide a photocopy of a valid driver’s license. Delivery is defined as the time at which physical possession of the car is transferred from us, the seller, to the buyer or the buyers’ agent or chosen transport company.

If you are not sure about something, Please ASK. Do not assume anything not listed is included. We reserve the right to cancel bids for excessive negative feedback. We reserve the right to end the listing if the vehicle is no longer available for sale.