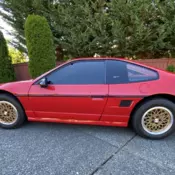

Electric 1988 Pontiac Fiero GT

| Make: | Pontiac |

| Model: | Fiero |

| Type: | Coupe |

| Trim: | GT |

| Year: | 1988 |

| Mileage: | 152,571 |

| VIN: | 1G2PG1194JP221692 |

| Color: | Green |

| Engine: | Electric |

| Fuel: | Electric |

| Transmission: | Manual |

| Drive type: | RWD |

| Interior color: | Tan |

| Drive side: | Left-hand drive |

| Vehicle Title: | Clear |

| Item location: | San Ramon, California, United States |

1988 Pontiac Fiero GT Additional Info:

Up for auction is a 1988 Pontiac Fiero GT that has been converted to electric drive. Are you interested in an electric vehicle but you don’t want to drive one of those cookie cutter OEM models? You will definitely stand out as I have for the past six years in this EV. I rarely have been able to go anywhere in this car without getting asked a lot of questions by curious persons. 98% of those people have given the car a great deal of praise. The other 2% simply don’t get the whole EV thing. It has always been a hit at the local car shows. What I’m offering here is a bargain for anyone that has considered doing a build of their own but could not afford the money needed, or felt that maybe they didn’t have sufficient technical ability. Most everything has been done for you and all of the high dollar build costs paid for. As you read the description below you will find a few items that you may or may not feel need further consideration.

The conversion was completed in late November of 2011 and up until a few months ago it had been used as my daily driver. During its time as a commute vehicle it accumulated nearly 63,000 all electric miles. At the time the conversion was completed the odometer read 89,571.4 miles. The odometer was then reset to zero so that it would indicate only the miles driven in electric mode. This means that the car has actually covered a total distance of around 152,571 miles in its lifetime. (This is the only issue that shows up in the CarFax report.) At the time that the car was converted, the only production EVs available were from Tesla and Nisan. The Tesla was too expensive and the Nisan unattractive and it had to short of a range. Given the blood, sweat, and cash invested in this project, and the slow rollout of OEM EVs, it looked as though this car would be driven until its wheels fell off. Then, this year GM introduced the Bolt EV. A new Bolt EV has since replaced the Fiero as my daily zero emissions commuter. As a long time Fiero enthusiast (this is copy #6 since 1984) I’m looking forward to purchasing copy number seven so I can once again participate in the activities of my local Fiero club. This is why this car is now being offered at auction.

The following is a description of the conversion: The original (and now freshly rebuilt) Getrag 5 speed manual transaxle with a custom bell housing adapter is mated to an HPEVS AC50 motor. A new flywheel and clutch kit have also been installed. The AC50 motor makes approximately 76 HP and 120 pound feet of torque. (Note: Less than 20 HP is all that is needed for this car to maintain 65 MPH.) The motor controller is a Curtis 1238-7601 which produces 650A/phase. Both the motor and the controller are air cooled so there are no fluids to worry about. The battery pack consists of thirty-four Thundersky 260 AH prismatic LiFePO4 cells connected in series. These cells are rated at up to 3000 cycles and are the safest and most stabile lithium chemistry currently used in electric vehicles. Their only drawback is lower energy density than Lithium cobalt or Lithium manganese cells. The nominal pack voltage is 113.9V. The total stored energy is then 29,614 WH. The pack is broken into three boxes so as to distribute the weight. A stock Fiero GT has a 44/56 weight distribution and this conversion has a nearly balanced 48/52 distribution. The post conversion weight is 3,190 LBS which is just 400 LBS over stock. Since 292 of those pounds went to the front of the vehicle it was necessary to install custom front coil springs. The springs were the only mandatory suspension modification. The sway bar end links had previously been upgraded to zero lash units from Rodney Dickman’s Automotive Accessories. The vehicle handles very well and is very confidence inspiring to drive. Originally the car had a 2.5 KW on-board charger but that has since been upgraded to a 5 KW unit. When plugged into a standard J1772 charging station at 240 VAC, it can add up to 17 miles of range per hour of charging. A separate charge cord with a Yazaki J1772 connector will be included with the vehicle for opportunity charging at 120 VAC outlets. Note that at 120 VAC it takes considerably longer to fully charge the pack. Also included in the auction is a Curtis hand held programmer which is a $500.00 value. Although the motor controller has been fully configured; the new owner may want to modify the settings to suit their preferences. The motor controller came with a Curtis Spyglass display instrument that was never incorporated into the vehicle. That will also be included as well as a gage pod that mounts to the A pillar. Over the last year or two the entire braking system has been replaced in increments. I was not satisfied with the brakes until the last upgraded components were installed. The four rubber flex lines were replaced with stainless braded hoses. That finally brought the stopping power up to the proper level. The traction pack has a BMS. This version of BMS is a monitoring rather than managing system. This means that it does not incorporate active cell balancing schemes which have proven to be dangerous when improperly designed and implemented. Instead, this system works with the pack charger to pause charging in the event that a high cell is detected. The system cycles the charger on and off until the total pack voltage has rippled its way up to 124.1 V. That value is equal to 3.65 V/cell which is the end of charge per the battery cell spec sheet. The individual cell modules also monitor for low cells during discharge. In both High and Low cell conditions a piezo alarm sounds. Should the alarm sound while the vehicle is being driven, the operator must immediately pull over and shut down the system. An overly discharged cell can be forced into a reverse polarity condition which will destroy the cell. This situation will only occur when the driver is attempting to squeeze every electron out of the pack. This is therefore not a recommended behavior. The brake system uses a 12 V electric vacuum pump to feed the brake booster. This was necessary due to the absence of engine derived vacuum. The 12 V systems are powered from a DC/DC converter that takes the traction pack voltage and converts it to 12 V. This is necessary due to the absence of a motor driven alternator. The vehicle is no longer equipped with AC but it does have a heater. The original heater core has been replaced with a ceramic PTC array. This array can produce up to 1500W of heat. However due to its 120V requirement it is most effective at full pack voltage. The available heat is reduced as the pack voltage drops. In my local climate zone this has proven to be adequate but it may not be so in yours. The solution is to either build a boost supply to drive the array at 120 V, or find a lower voltage array and feed it from a duty cycle limiting supply. Using the heater has only about a 5% effect on the vehicle’s range.

Expected lifespan of the battery pack: For those unfamiliar with lithium batteries I provide the following critical information. Regardless of the particular version of lithium cell the industry agrees that once the cell has lost just 20% of its original capacity it has thus used up its rated cycle life. It is important to consider that the cell still has 80% of its original capacity. This means that the vehicle can still do 80% of what it could do when its cells were first installed. Based on this behavior it is not unrealistic to expect up to 250,000 miles of life from this pack. However, the other systems in the vehicle may not go quite that far; but obviously the pack is by far the most expensive component in the vehicle. This pack originally cost just under $14,000.00.

Performance: Stoplight performance is adequate with the occasional surprise to the driver next to you. When the other drivers aren’t seeing a dragstrip Christmas tree instead of a traffic signal, this car will usually jump out ahead of theirs. Top speed achieved thus far is an even 100 MPH. The car reaches 80 MPH in fairly short order but getting from there to 100 requires a stretch of road as well as very specific environmental conditions such as temperature, humidity, grade, and daylight. Daylight because the car is more aerodynamic with the headlamp doors closed. Speeds above 80 should generally be limited to short duration due to the system being air cooled. Also range is dramatically reduced at high speeds. The car has traveled as many as 105 miles on a charge on two occasions. However those identical trips involved a mix of speeds and driving conditions. I have determined that 65 to 70 MPH freeway trips consume about 330 WH/mile which limits the range to about 84 miles. I should also mention that this vehicle does not do well on steep grades at freeway speeds above 60 MPH. It is fine at city speeds going up and down hills such as in San Francisco, but speed falls off on long tall grades at high speed. Downhill driving is made easier thanks to regenerative braking. The car is configured with throttle-off regen. As you back the pedal off kinetic energy is converted back into electrical energy and put back into the traction pack. This ever so slightly increases the vehicle’s range, perhaps by 3%. It also takes load off of the friction brakes.

Instrumentation: The car’s original gas gage is now driven from a Zeva electronic module that measures amp-hours in and out of the traction pack. It uses that measurement to apply a proportional PWM signal to the stock dash mounted fuel gage. I use the trip odometer in concert with the fuel gage. The trip odometer gets reset every time the pack is fully charged. As yet there is no instrumentation of pack voltage which would provide useful information as the bottom of the discharge curve is approached. Perhaps the next owner will implement a gage for that. The stock tachometer is also used. A magnetic sensor has been implemented on the aux shaft of the motor which sends the required three pulses per rotation to the gage. Conveniently the electric motor is limited to the same 6500 RPM that the gage tops out at. The Fiero gage cluster includes a voltage gage for the 12V system. Monitoring this gage at start-up is how the operator knows that the system has in fact started. The needle passes midpoint indicating that the system is up and running.

General items: This car started out as a restoration project prior to the green light being given for the electric conversion. In 2010 and early 2011 the interior of the car was removed and everything steam cleaned. A new Fiero Store plastic backed headliner was installed. The center console was repainted and the driver’s seat got replacement leather. The interior still looks pretty good but is again showing some signs of the passage of time. There are no rips or tears but service and car wash personnel have begun to wear a spot on the outside bolster on the driver’s seat. Long ago I figured out a method for getting in and out of these cars that avoids wear to the bolster, but unfortunately it is seldom convenient to pass along the technique. The exterior was repainted about two years ago and still looks quite good from a short distance and further away, however there are some chips and dings on the nose and hood. There is also a stress crack under the paint in the hood where the hood boxes in the passenger side headlamp door, again only noticeable from up close. Some touchup paint in both gold and green will be provided. The factory AM/FM cassette radio has been replaced by a Retro Sound Newport model. This radio features USB ports as well as AUX inputs. It also has a Bluetooth hands free interface for your phone that lets you answer calls and stream music. The microphone is mounted under the dash. This radio was also designed to look like a GM factory unit. Rear panel RCA connectors facilitate the use of external amplifiers and equalizers. This Fiero left the factory equipped with the optional Performance Sound system which added an in dash sub-woofer. The driver in the sub cabinet has been re-coned and works very well. The other four speakers in the system have been replaced with aftermarket units that also work well. I mentioned earlier that the car had been painted. Recently I looked under the car and found gold overspray. I can’t imagine how the paint shop managed to get paint there but where the gold paint got sprayed over the dusty dirty black underside it looks just like rust. Fortunately this is a 100% California car that has no rust. Included, and I think you will agree is necessary; is a documentation package. The package will include an addendum to the owner’s manual describing the slightly different driving experience that is associated with owning and operating this vehicle, along with its unique maintenance items. Also included in the documentation package will be schematics for all of the added systems and how they interface with the factory systems. All of the pertinent data sheets and user manuals will also be included. the windshield has an arc shaped scratch on the driver's side due to a stone getting trapped under the wiper blade.

The auction: This 1988 Fiero GT is being sold as is with no warranties expressed or implied. Transportation of the vehicle is the buyer’s responsibility; however I will work with your shipper. A $500.00 PayPal deposit is requiredwithin 24 hours after the auction is closed. The winning bidder will then have ten days to pay the balance in cash or by bank money order and claim the vehicle. No personal checks will be accepted. The existing title is free and clear. It can be signed over to the new owner at the time of final payment. The reserve price is set at a number that is less than the cost of the build components alone. Thank you for your consideration.